- Home

- About Us

- Products

- AC Test Systems

- Capacitor

- Corona Rings And Shielded Rings

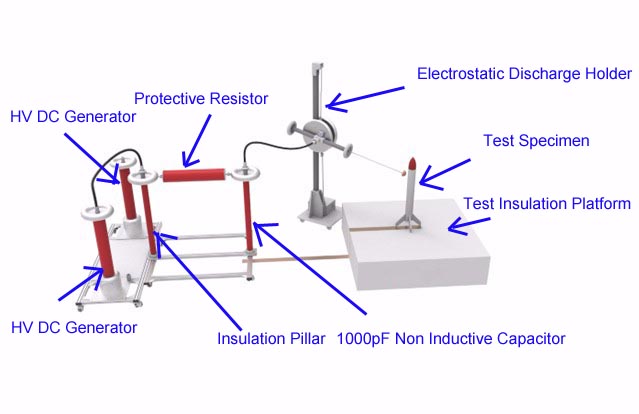

- HV DC Generator

- Impulse Current Test Systems

- Impulse Voltage Test Systems

- Partial Discharge Test System

- Resistors

- Transformer Test Falicilites

- Other Test Instrument

- Voltage Divider

- Variable Inductance AC Resonant Test Systems

- Variable Frequency AC Resonant Test Systems

- News & Events

- Downloads

- Contact Us